The OSD Expansion Project

This project was expansion of existing OSD facility, which is engaged in CMO manufacturing. The planned expansion was on large scale up of the facility which will enhanced the overall production capacity of the plant. This facility is designed to meet the requirement of domestic as well as international regulatory driven market like Japan FDA, PIC/s, EU and US FDA.

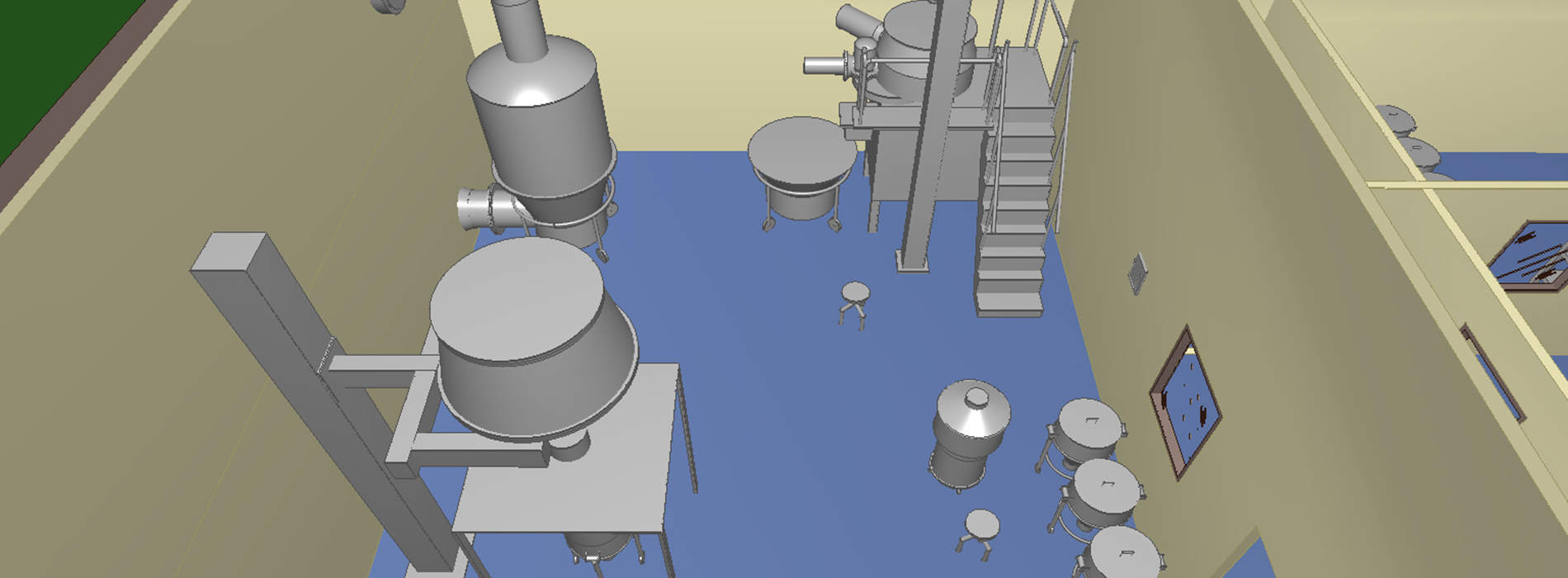

The conceptual design and basic engineering of the entire expansion was done as single phase but detailing was splitted into two phases. This expansion was as good as Green field projects inclusive of construction of civil structure and scale up of all support functions.

Facility is designed for the output of 3500 Mio units per annum with various packaging as blister and bulk bottle pack.

Since this was planned as expansion of the existing approved facility which was already running full capacity of production, the layout was design to integrate the existing facility so that seamless operation can be performed. The layout has been design based on current GMP regulations however there were multiple challenges for seamless integration due to old existing facility and SOP. The connectivity of the technical services area was another challenge due to old existing operation philosophy & utility services.

However all such challenges were well know from day one while we started conceptual design philosophy of the expansion. There were couple of surprises as we walk through design but manageable. So while doing design, engineering & capacity estimation of utilise, provision is done to make old existing utilise as redundant if required.

The layout of the entire facility and technical service area is done with due consideration of maintenance, operation, accessibility and future modification within tight investment budgets. Similarly, special consideration has been given to reduce the travel distance & travel time of various raw material from the warehouse to respective production blocks while making fully utilisation of common facility and infrastructure of the warehouse

The provision for the phase 2 of future expansion was planned in such a manner that it can be easily integrated with other common infrastructure and utilities without much break down. So the strategy for phase 2 was plug & play which would drastically reduce the loss of production.

Elomatic was sole design and engineering consultant for the project. The facility has been design under the compliance of local statutory norms as well as reputed international norms. The investor who are one of the leading player in OSD CMO business, appreciate the overall role played by Elomatic. This project once again established the leadership of Elomatic with the investor and regulatory body. Needless to mention the comprehensive role played by our inhouse design & engineering tools inclusive of EloDoc™ system and CADMATIC™. Due to which we could generate error free design and clash free engineering, making life much easy for the implementation of the project.

The project was successfully completed in record time schedule and within the tight investment budget.